T: +86-577-59970799

E: wpt0125978@163.com

E: wpt0125978@163.com

No.17 Binhai 3rd Road, Yongxing Street, Longwan District, Wenzhou City, Zhejiang Province

| Availability: | |

|---|---|

| Quantity: | |

|

Overview

WUG Series Intelligent Ultrasonic Gas Meter is a kind of intelligent metering instrument, which adopts ultrasonic time difference method and unique new patented structure to measure the medium flow rate, and is suitable for the flow measurement of natural gas.

| Performance Features

1. High metering precision, good stability:

Simple structure, small size, no moving parts, no mechanical wear and tear, no magnetic field effect.

2. High sensitivity:

Instantaneous flow monitoring is possible to cope with all kinds of technical means of gas theft. Real-time temperature and pressure corrections are also possible, effectively improving supply and sales differentials.

3. High security:

It can prevent the leakage of small flow, shut down the valve for protection according to the setup plan, and has the functions of alarm for reverse meter loading and shutting down the valve, management of abnormally large flow, and monitoring of illegal meter dismantling behavior.

4. Long life, maintenance-free:

Immediate accuracy correction via NIR interface, no parts to replace, no return to the factory, easy maintenance.

5. Strong scalability:

Fully electronic structure, easy to expand other functions, such as remote recharge, valve control, alarm, etc..

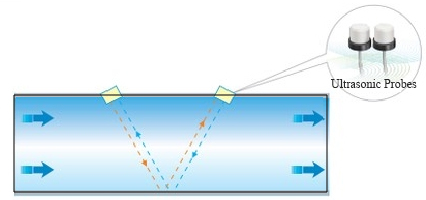

| Working Principle

Ultrasonic gas meter to measure the relationship between the time of propagation of sound waves in a flowing medium and the flow rate as a principle. It is generally believed that the actual propagation speed of sound waves in the fluid is composed of the propagation speed of sound waves in the stationary state of the medium ( cf ) and the axial average flow velocity of the fluid (vf

cf ) and the axial average flow velocity of the fluid (vf ) in the direction of sound wave propagation component. As shown in FIG.1, the relationship between the propagation time and the quantities in the downstream and countercurrent flow is:

) in the direction of sound wave propagation component. As shown in FIG.1, the relationship between the propagation time and the quantities in the downstream and countercurrent flow is:

In the formula:

tup —— Ultrasonic wave propagation time against the flow in a fluid

tdown —— Ultrasonic wave propagation time downstream in a fluid

L —— Channel length

cf —— Speed of sound wave propagation in a fluid

vf —— Average axial flow rate of the fluid

φ —— Channel angle

FIG.1

An expression for the fluid flow rate can be derived using two formulas:

Multiply the overflow area A , to get the volume flow rate

, to get the volume flow rate  vf, for example:

vf, for example:

![]()

|

Key Technologies

FIG.2

1. Ultrasonic flow measurement technology

2. More stable flow field

3. Small pressure loss

4. Anti-fouling

|

Technical Parameters

Product name | Commercial Ultrasonic Gas Meter | Household Ultrasonic Gas Meter | ||||||||

Aluminum housing | Steel housing | |||||||||

Model specification | WUG -G6 | WUG -G10 | WUG -G16 | WUG-G25 | WUG -G40 | WUG -G65 | WUG-G1.6 | WUG-G2.5 | WUG-G4 | |

Measuring range (m³/h) | 0.06 ~10 | 0.1 ~16 | 0.16 ~25 | 0.25~40 | 0.4 ~65 | 0.65~100 | 0.016~2.5 | 0.025~4 | 0.04~6 | |

Interface mode | Screw thread, G1-1/2 | Screw thread, G2 | Screw thread, G2-1/2 | Screw thread, M30×2 | ||||||

Dimensions (mm) | 246×204×110.5 | 330×244×167 | 330×248×167 | 232×172×135 | ||||||

Weight | 2.3kg | 4.3kg | 1.6kg | |||||||

Battery | ER34615/3.6V | |||||||||

Accuracy class | Level 1.5 | |||||||||

Measurement errors | Qmin≤Q<Qt | ±3% | ||||||||

Qt≤Q≤Qmax | ±1.5% | |||||||||

Working pressure | 0~30kPa | 0~20kPa | ||||||||

Working temperature | -25℃~55℃ | |||||||||

Storage temperature | -30℃~60℃ | |||||||||

Explosion-proof grade | Ex ib IIB T4 Gb | |||||||||

Protection class | IP65 | |||||||||

|

Installa tio n and external dimensions (unit: mm)

WUG-G1.6/2.5/G4 Gas Meter Installation Dimension Drawing

FIG.3

WUG-G6/G10/G16 Gas Meter Installation Dimension Drawing

FIG.4

WUG-G25 Gas Meter Installation Dimension Drawing

FIG.5

WUG-G40/G65 Gas Meter Installation Dimension Drawing

FIG.6

| Ordering Instructions

The meter model number marking consists of the product name, flow rate specification. The detailed format is annotated below. The module model number's consists of the following parts of the product:

FIG.7